GKN: Shropshire firm kept the wheels of industry turning

As the firm fights off a hostile takeover bid, GKN is a company that is worth fighting for, says Toby Neal. Here's why.

Well, where do you start with GKN Sankey?

It is a Shropshire firm which kept Britain rolling. That's the wheel division.

Sankeys made wheels for everything from huge trucks to wheelbarrows, exported all over the world.

It blew things up - that's bombs, mines, depth charges. And shot things down. Almost a thousand Spitfires were made at the massive Hadley Castle plant.

Our fighting forces have gone into battle in armoured vehicles made at Hadley.

People have phoned home from kiosks made there (the shiny aluminium ones, not the traditional red ones).

Down on the farm there were ploughs, trailers, and manure spreaders.

Getting thirsty? Have a cuppa, courtesy of a vending machine made by... well, you should be getting the idea by now.

We have only scratched the surface of the range and diversity of Sankey's work, but if you mention the company's name, it is perhaps the motor industry which comes most quickly to mind.

GKN takeover battle latest:

If you want to know how important the firm has been, let us flashback to an unofficial strike at GKN Sankey at Hadley in 1970 involving over 5,000 workers - and that's not a misprint, because Sankeys was one of Shropshire's major employers.

That strike saw much of Britain's motor industry grind to a halt, with over 25,000 workers made idle nationwide.

Whenever you took to the road in a British motor vehicle, the chances were that it had been built using Sankey's products.

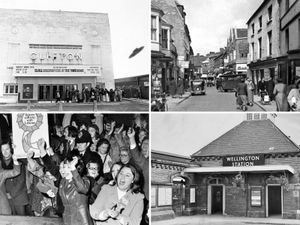

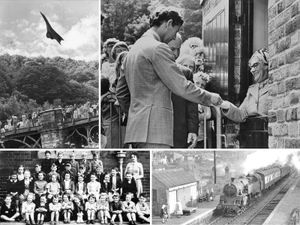

Historically Sankeys has been much more than a firm. It has been a community in itself, as well as being a leading player within the local community.

It had a rifle club, a chess club, a bowling club, a gardening club, a badminton club, a caravan club, darts, a thriving male voice choir (which called it a day as recently as 2015) - once again, we could go on and on.

There was even a works fire brigade and a company magazine, The Sphinx.

Tennis courts, bowling green, social club... Sankey's stadium, now built over by housing, was one of the finest football grounds in Shropshire.

In the company's centenary year of 1954 a £10,000 gift by the firm made possible the opening of a new recreation ground at Hadley.

How times have changed. Today GKN Sankey, which once had 5.8 million square feet of factory space, is a shadow of its former self.

It still makes wheels, among other things, and employs 340 people at Hadley, a fraction of the workforce in its heyday when busloads of workers were brought in from as far away as Ludlow.

The story begins in 1854. Joseph Sankey was a workman making tea trays for japanning in a workshop behind a pub in Bilston, and in that year teamed up with another workman called Jackson.

Under Sankey's leadership the business increased its product range and expanded, and at the turn of the 20th century started to tap into the motor revolution, making panels and fittings for cars.

In a crucial move, it developed and patented the first pressed and welded detachable steel car wheel, which was far superior to the wooden wheels previously used.

To cope with demand from the motor industry the company bought the Castle Car Works at Hadley in 1910 - covering around five acres, the site had previously made tramcars. The motor body and wheel making departments were transferred to the Shropshire plant, with between 100 and 150 personnel coming over from Bilston.

It was known as the Hadley Castle works, from the castellated Hadley Castle building nearby.

It was the start of something big. Local recruitment began immediately. By 1911 Sankeys was producing all-steel bodies not only for cars but also for buses, charabancs, and commercial vehicles.

The Great War saw it producing everything from bombs and field kitchens to armoured cars and aircraft struts, along with normal output of wheels and bodies. Post war, steel furniture was added to the long list of products.

It was after the Great War too that GKN came on the Sankeys scene - Sankeys became a subsidiary of Guest, Keen & Nettlefolds in a merger effective from January 1, 1920, but retained its own identity within the group.

Incidentally the John Guest whose name is included in Guest, Keen & Nettlefolds was originally from Broseley.

What have we left out of the Sankeys story? Inevitably, lots, but perhaps we'd better mention chassis frames and plastics.

Time for another drink. Thanks, of course, to the Sankey System - as the firm's contribution to the brewery industry, comprising plant, containers, and fittings, was known.